Large scale FD dryer

Classification:

Key words:

Large scale FD dryer

Hotline:

Fax:

Large scale FD dryer

HTFD (1500L, 2000L, 2500L, 3000L, 3500L) is mainly suitable for large-scale production of large enterprises. It is used for deep processing of agricultural and sideline products, fruits and vegetables, aquatic products, Pet food, convenience food, leisure food, etc., with high production capacity, low operating costs, high profits, large dry area, and large water treatment capacity. Ice melting adopts thermal shelling+warm water defrosting or steam defrosting. Melt and discharge within 40 minutes after the batch cycle.

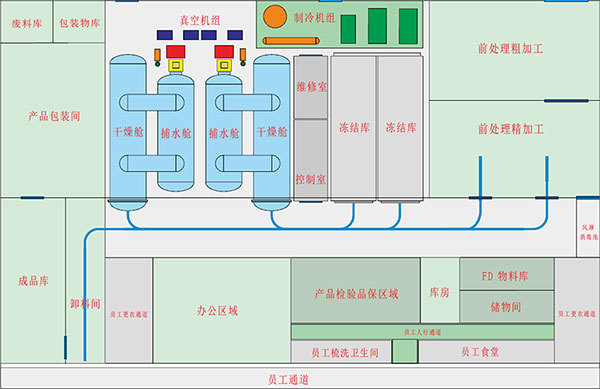

Workshop Design Cases

Prepare to freeze the warehouse

Prepare to freeze the warehouse

6-8 hours per batch, fully meeting the 24-hour freeze-drying production process, using a "first in, first out" cycle.

Suspended material truck rail transportation

The material tray of the hopper car is equipped with predetermined weight of raw materials, which enter the drying device. After drying, the hopper car exits the discharge, and the system is simple, hygienic, and safe for feeding.

HTFD type freeze-drying machine

Automatic/manual control, each drying cycle only needs to close the cabin door, set the process parameters, press the start button, and enter the drying process.

Heating system

Radiation heating, with a temperature range from room temperature to 120 ℃, and precise control of the drying process, ensures high-quality product quality.

Vacuum system

By selecting an imported vacuum pump with high efficiency and large flow rate, the required vacuum degree can be achieved within 15 minutes.

By selecting an imported vacuum pump with high efficiency and large flow rate, the required vacuum degree can be achieved within 15 minutes.

Ice melting system

Batch ice melting, utilizing batch interval time, ends the ice melting within<30min between discharge and input time, without occupying drying time.

Refrigeration system

Adopting a large unit parallel system, each condenser shares a common system, with staggered operation and energy saving and consumption reduction.

PLC/PC control system

The Siemens PLC module control system is selected to ensure the optimal working state of the freeze-drying process, material freezing, drying, heating medium, vacuum, and refrigeration systems. Remote devices can also be installed to achieve remote control.

Technical Parameters Table of HTFD Equipment Products

| Model | Dehydration capacity/L | Heating area/m² | Temperature range/℃ | Material quality | Cold source | Overall dimensions/m | Applicable scope |

| HTFD5L-0.5m²/R | 5L | 0.5 | Ordinary temperature—95℃ | Stainless steel(SUS304) | Direct inflation R22 R404A | 1.2×1.2×2.0 | Testing machine |

| HTFD50L-3m²/R | 50L | 3 | 2.0×2.2×2.0 | ||||

| HTFD150L-10m²/R | 150L | 10 | Ф1.8×4.5 | Suitable for: Traditional Chinese medicine, health category. Vegetables and fruits, mushrooms, aquatic products, poultry meat, Pet food, agricultural and sideline products deep processing. | |||

| HTFD300L-20m²/R | 300L | 20 | Direct expansion barrel pump for liquid supply R507A R717 | Ф1.8×6 | |||

| HTFD400L-30m²/R | 400L | 30 | Ф1.8×7 | ||||

| HTFD750L-50m²/R | 750L | 50 | Ordinary temperature—120℃ | Carbon steel/stainless steel(Q235/SUS304) | Ф2.3×7.6 | ||

| HTFD1200L-100m²/RA | 1200L | 100 | Ф2.3×11 | ||||

| HTFD2500L-200m²/RA | 2500L | 200 | Ф2.3×12.8 | ||||

| HTFD3000L-240m²/RA | 3000L | 240 | Ф2.5×12.8 | ||||

| HTFD3500L-300m²/RA | 3500L | 300 | Ф2.5×15 |

Online consultation

Related Products